Sep 26 , 2024

Plasma-Moly Ring Technology: Enhancing Performance with Advanced Materials

When it comes to engine performance and lifespan, piston ring technology is paramount. It's critical to minimize friction and wear in high-performance engines, since every horsepower counts. Plasma-moly ring technology is an innovative approach that is transforming the way engines work at their best.

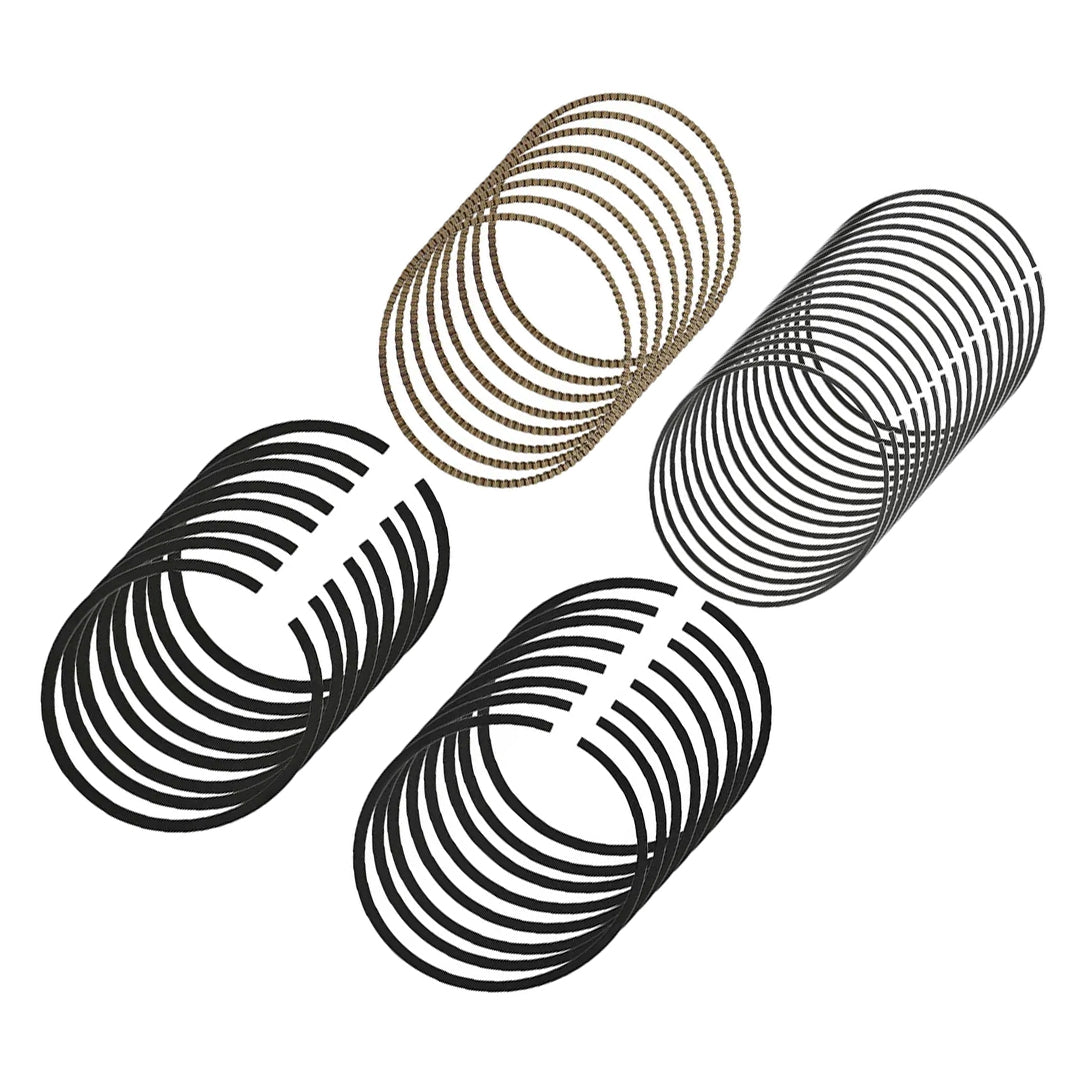

Understanding Plasma-Moly Rings

Plasma-moly rings are a kind of piston ring that has a molybdenum compound applied to it utilizing plasma spray technology. This procedure involves heating molybdenum particles to extremely high temperatures, which then propel them at high speeds onto the ring's surface. The end product is a coating that is thick and homogeneous in texture and adheres strongly to the substrate. Coatings made of molybdenum and other elements are usually mixed to get the best possible hardness and lubricity. The plasma-moly ring outperforms the more conventional ring materials in terms of hardness, wear resistance, and friction reduction.

Benefits in Reducing Friction

A major benefit of plasma-moly rings over regular rings is the much-reduced coefficient of friction. Increased engine efficiency and power production are direct results of this decrease in friction. In addition to keeping operating temperatures ideal under high-stress conditions, the molybdenum coating also has outstanding heat dissipation capabilities. Reduced blow-by and oil consumption are additional positive effects of the improved sealing and oil management that add to the engine's efficiency. This combination of features significantly reduces friction-induced power loss, which can increase fuel economy in racing and everyday use.

Advantages in Wear Reduction

Racing applications, where engine rebuilds are frequent and expensive, benefit greatly from plasma-moly rings because of their endurance in high-stress settings. The rings' ability to retain their performance characteristics even after extensive usage is crucial since it guarantees that the engine's output will remain constant.

Applications in High-Performance Engines

Because of its wear-resistant and friction-reducing characteristics, plasma-Moly ring technology has seen extensive use in professional racing engines, leading to significant improvements in performance. More and more high-output street engines, like some Ford crate engines, are using this technology to make them last longer and provide more power.

Conclusion

With its revolutionary plasma-moly ring technology, engine component design has reached a new level of excellence, providing noticeable improvements in engine performance, wear resistance, and friction reduction. Modern engine technologies are constantly improving their power and efficiency, which means that sophisticated materials such as plasma-moly coatings will play an increasingly important role.